Our factory has been certified by the GMPC, ISO22716, ISO9001 and Sedex. All our manufacturing process follows international standard of good manufacturing practice. Besides, our factory is also registered by FDA and we already pass the factory audit by Unilever, Watsons and Disney.

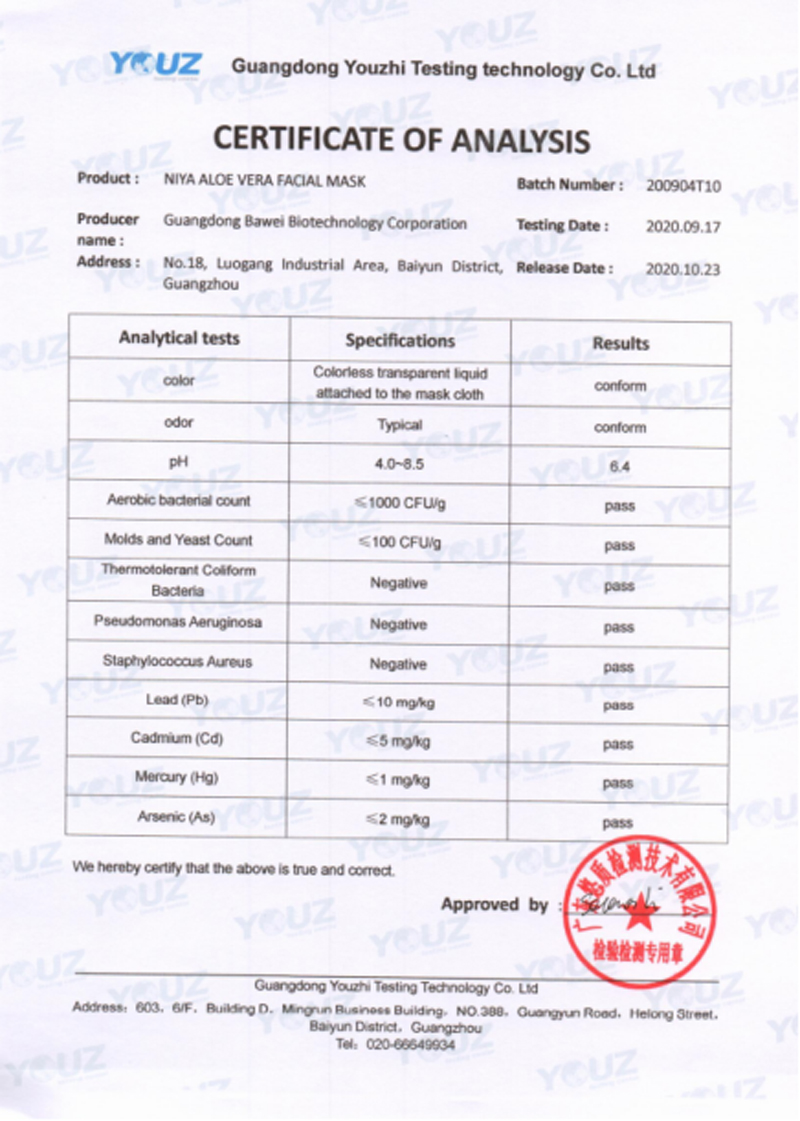

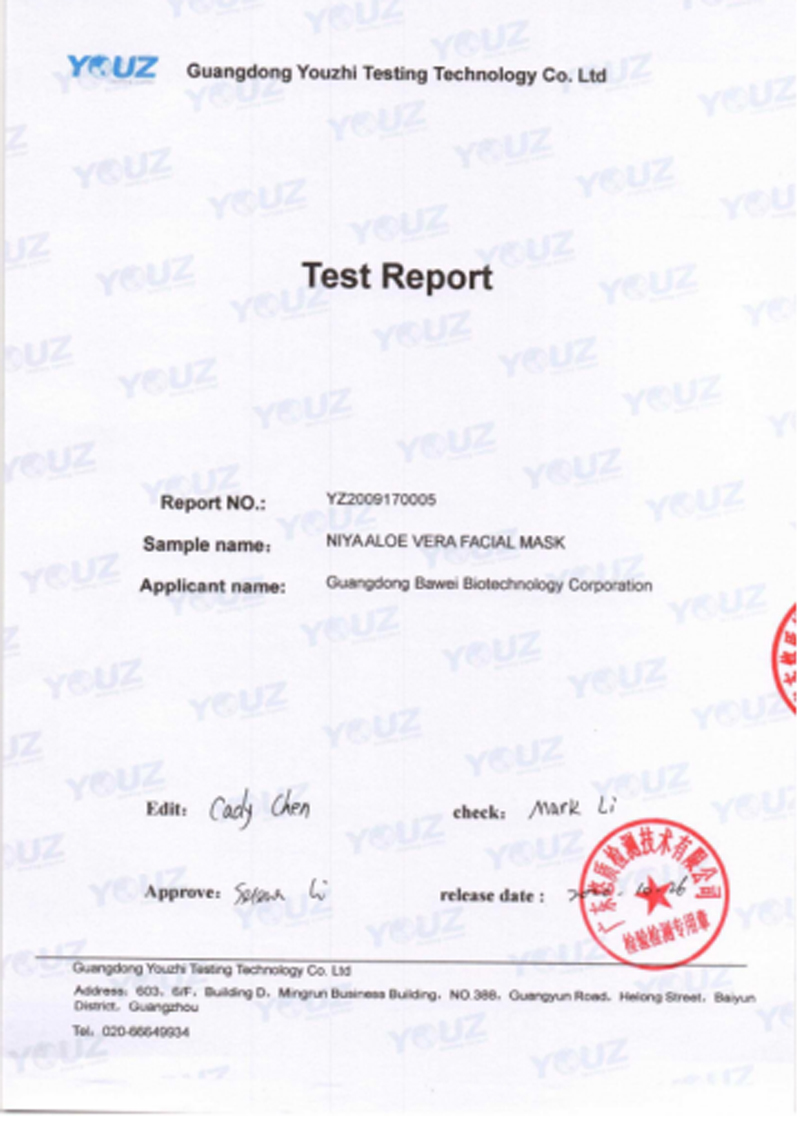

Committed to customer satisfaction, we start at the beginning - monitoring all raw materials and follow up with rigorous testing on a regular basis.

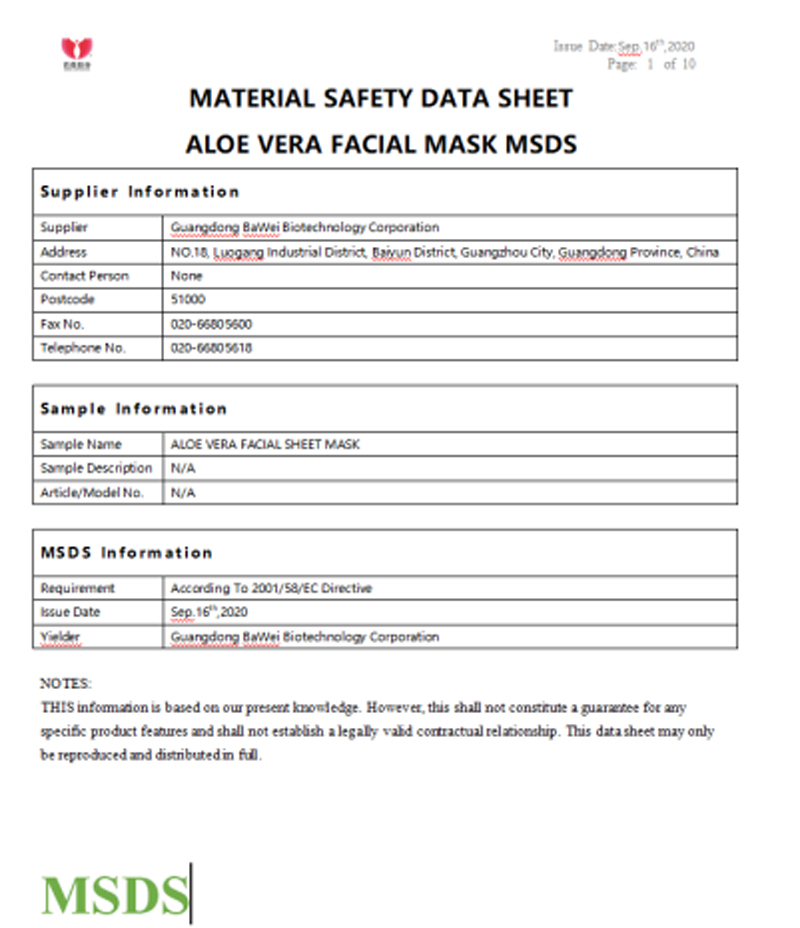

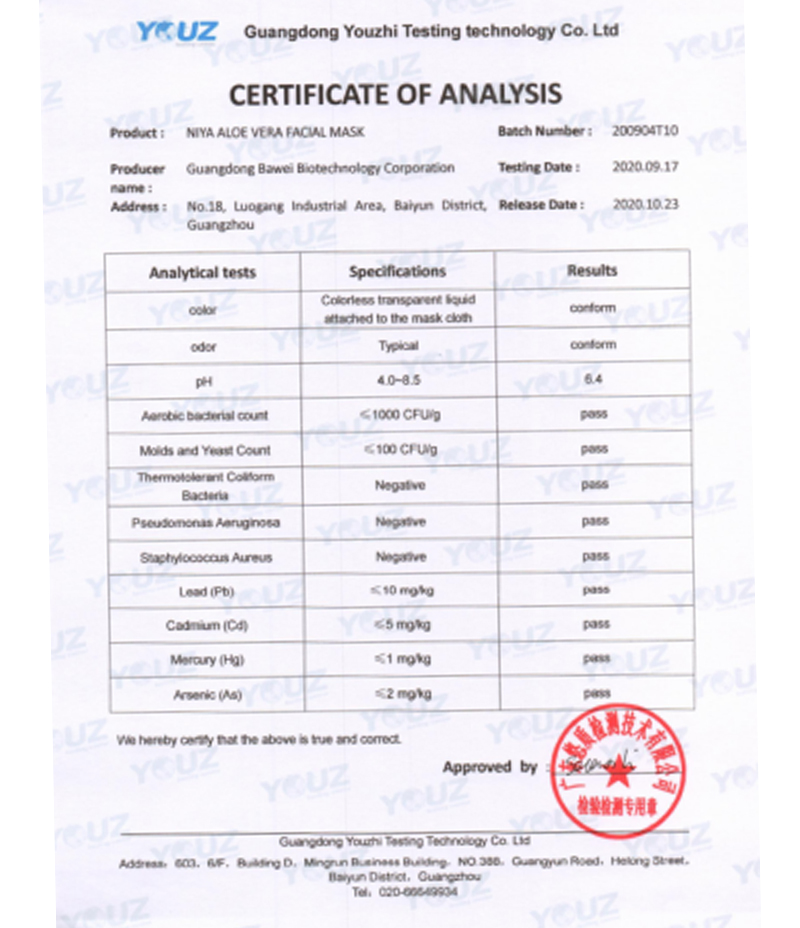

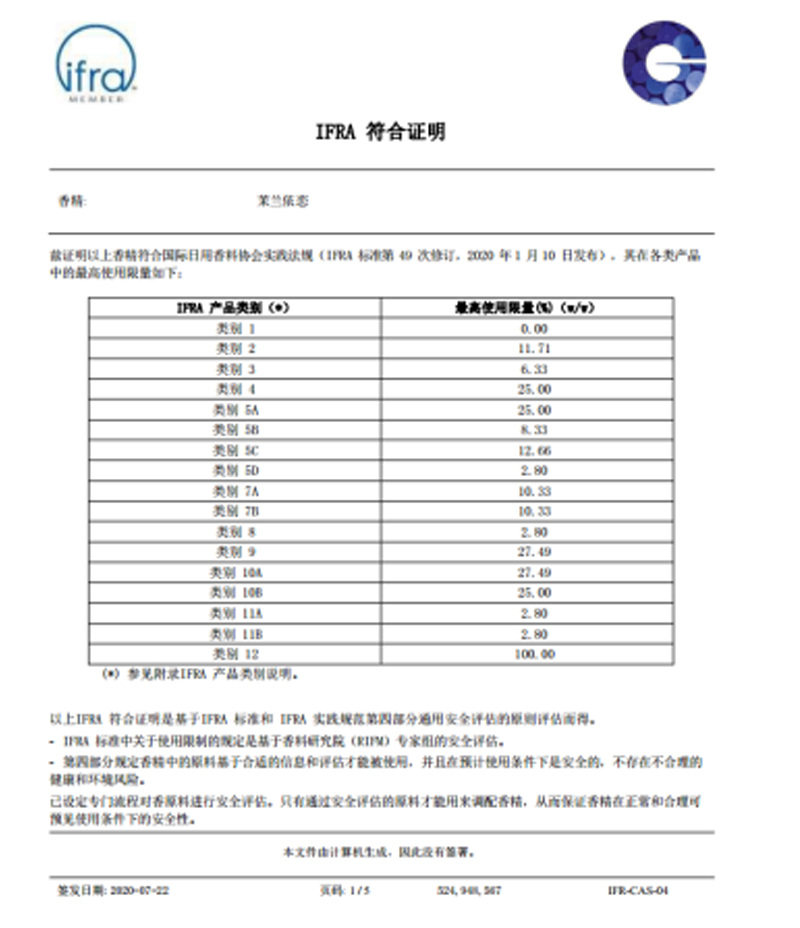

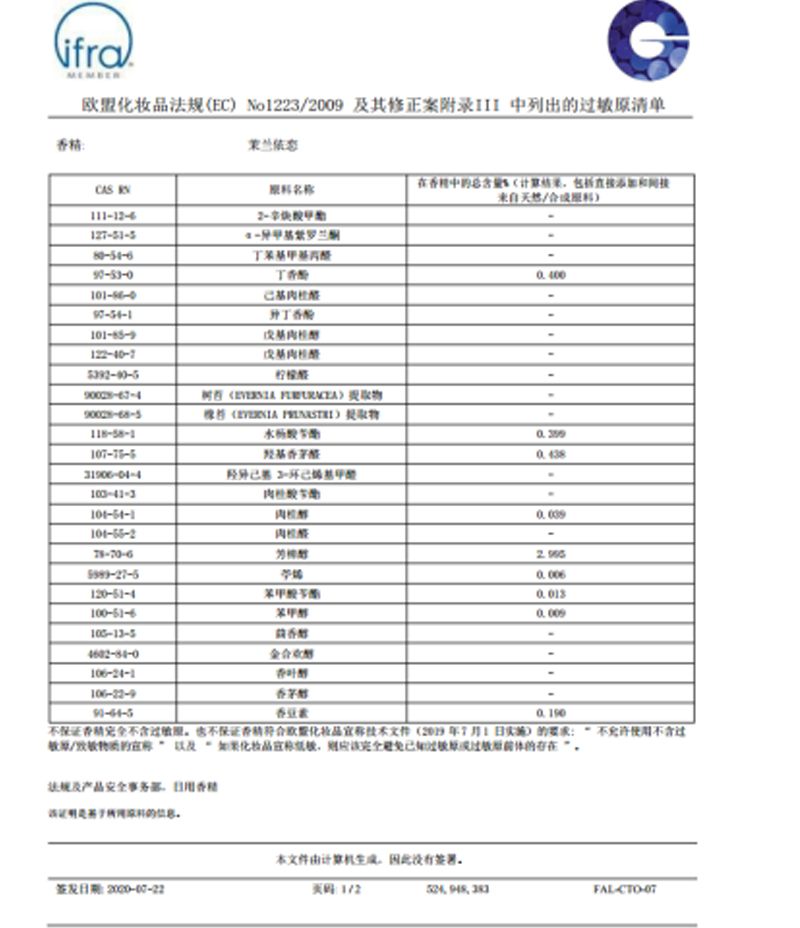

When a new raw material is introduced to our lab, the following docs are strictly required to check if it is safe.

After checking the docs, we follow up with rigorous testing on a regular basis.

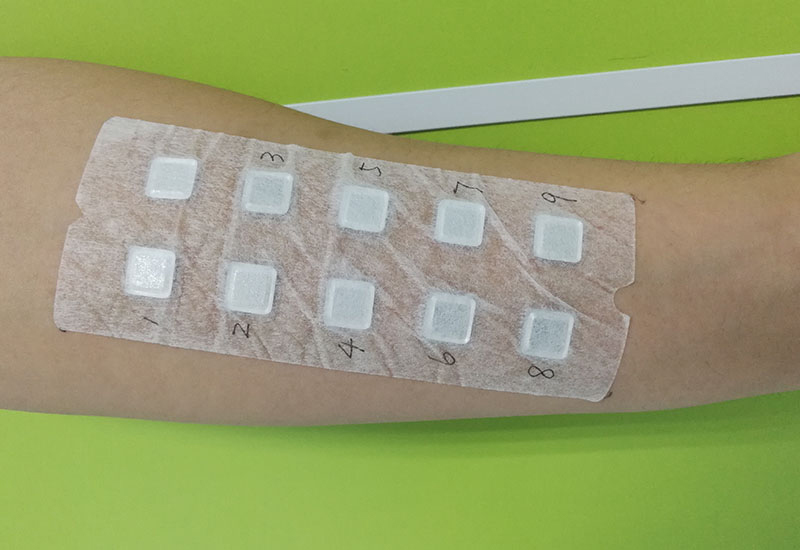

Test the raw material over a period of time to see if it will cause adverse skin reactions.

Check and analyze the function of packaging materials to ensure the user experience. The tests include seal test, adhesion of surface decoration, residual volume test, label stickiness test, waterproof & sweatproof test, etc.

Check the compatibility of packaging material and content to meet the packaging safety requirements. The tests include heat resistance, cold resistance, temperature resistance, solar radiation, etc.

Transportation simulation test to ensure the safety of products in the process of transportation, the tests include shock test and drop test.

Healthy volunteers or people with skin problems were used as subjects to evaluate whether the cosmetics had efficacy, or whether they had a positive effect on skin problems. The tests include spot-whitening, acne treatment, anti-aging, anti-inflammatory, eye bag removal, moisturizing, oil-control, after-sun repair, sensitive skin test, long-lasing test, coverage test, etc.

Cell tests is another testing method that we carry out to evaluate the efficacy of the product. By obtaining part of human skin tissue cells, and then give a certain amount of cosmetics, test some products produced in the process of cell development to evaluate the activity of cells or certain characteristics of cell content changes, to analyze the safety and efficacy of the product.

Products are inspected on the line by various kinds of equipment. Furthermore, there is visual appearance check by our staff: Weight inspection, Lot printing confirmatory inspection, Indication inspection, Damage and contamination inspection.

We called on all staff to participate in quality management activities, don't let a nonconforming product goes into the next process. Each workshop must strictly distinguish the qualified and defective products to be inspected to prevent confusion, and the products in the workshop must be neatly placed and kept clean and dry. Each workshop must standardize the operation and strictly ensure that no unqualified products are produced, no unqualified products are accepted and no unqualified products are delivered.

Pre-shipment inspection is the summary of the produced products and the re-inspection of the performance indicators of the whole product. Whether the products meet the needs and expectations of the customers must be inspected in strict accordance with the standards set by the company and the requirements of the customers, which includes Appearance inspection, Microbiological inspection, pH inspection, Viscosity inspection, Odor inspection, Specific Weight inspection and Quantity inspection.

We inquire and track the logistics situation of each batch of goods, and timely inform customers for the delivery. When the goods arrive at the destination, we timely follow up whether the goods have any abnormal quality issues caused by transportation. When the goods are sold to the local consumers, we timely follow up the feedback of the market, so as to constantly update and improve our products and service.